Benefit case study: Blue Ridge cuts inventory levels by 31% for a distributor

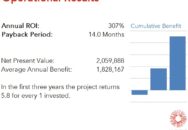

By deploying Blue Ridge Supply Chain Planning, this North America–based foodservice distributor replaced slow, historically driven ERP- and spreadsheet-based procurement with a more disciplined, forward-looking planning approach suited to a perishable, service-critical operating model. The shift enabled buyers to move away from fear-based ordering and manage inventory against defined service-level and days-on-hand targets, reducing average inventory levels from approximately 26 days to under 18, a 31 percent reduction, while maintaining availability for regional and national accounts. Improved forecasting and replenishment precision also reduced shrinkage and spoilage by roughly half across fresh and frozen categories, lowering direct product loss and associated handling costs. At the same time, standardized planning workflows enabled a significantly leaner buying team to support a larger, more complex business without adding headcount, reinforcing the link between planning discipline, service-level accountability, and scalable operational performance.