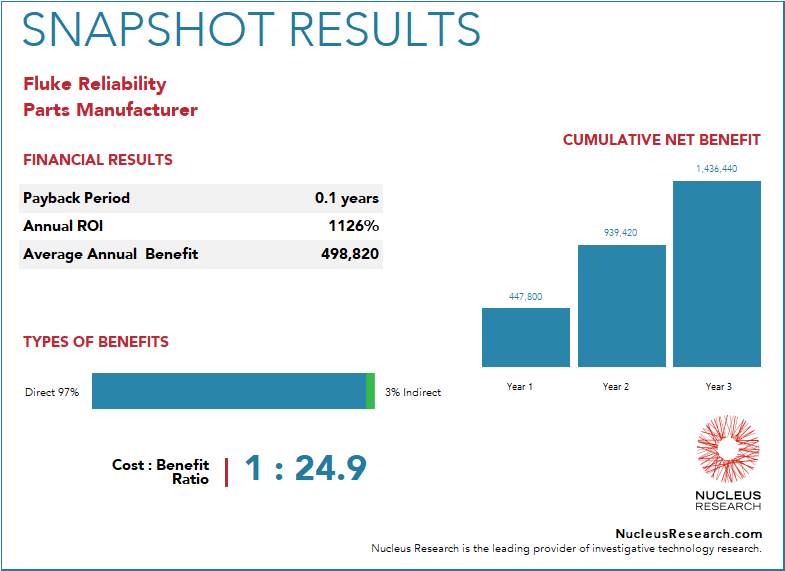

Fluke Reliability ROI case study – Parts Manufacturer

Have a specific question? Query our research catalogue with the Nucleus AI Tool.

An aerospace parts manufacturer achieved an 1,126 percent ROI and recovered its investment in 1.2 months following its Fluke Reliability eMaint deployment. Notable quantified benefits from its deployment include increased productivity, reduced downtime, and cost savings. Specific quantitative benefits cited include a 50 percent decrease in monthly corrective actions, saving up to 30 minutes per action. Equipment uptime improved from 80 percent to 95 percent, reducing downtime costs significantly. Overtime was cut by between 14 and 16 hours weekly, and the number of technicians was reduced from 14 to 9, saving roughly $65,000 per technician. Inventory per equipment was lowered by 10 percent, providing significant savings from the initial $1.2 million inventory. Replacing a costly $80,000 per year equipment with a $200,000 one-time purchase led to 100 percent uptime without recurring costs.

Learn more about Nucleus Research’s ROI case study approach here.

Gain the knowledge you need to effectively develop and deliver a financial business case at ROIUniversity.com.